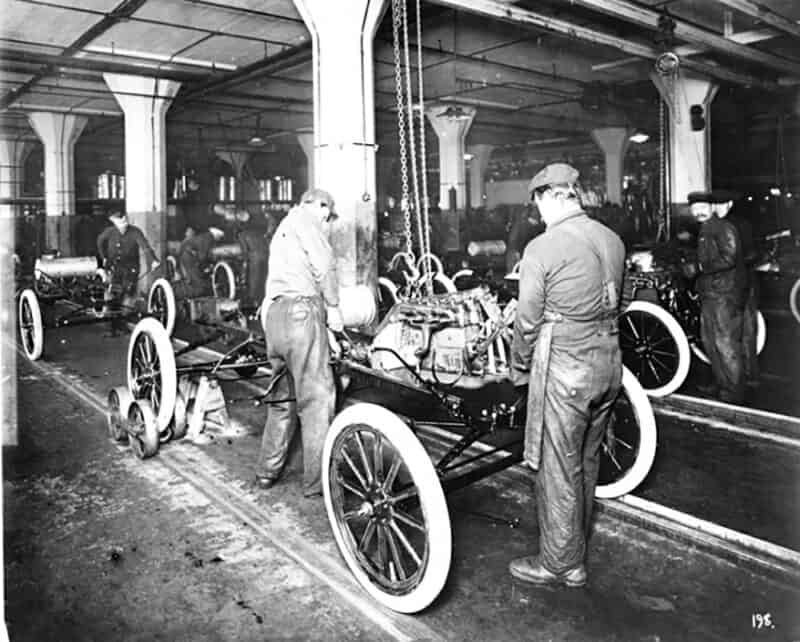

The moving assembly line was put into production at Ford Motor Company’s Highland Park Plant on December 1, 1913. Prior to this innovation, vehicles were built at a single workstation from the chassis up. Parts were brought to the cars, where workers performed the entire assembly process on a fixed platform. By implementing a moving assembly line, Ford reversed the process. Workers remained stationary as the vehicles being assembled moved past via a conveyor mechanism. Workers performed the same assembly task on each car as it passed.

This innovative assembly line dramatically increased the output of the Highland Park plant and Ford passed the savings on to his customers. The Model T cost $825 in 1908, and by 1925 the price had dropped to $260. Ford put America on wheels by making the “Tin Lizzie” so inexpensive that he sold 16.5 million Model T cars between 1908 and 1927. That’s 2,385 Model T sales per day, every day, seven days a week, 52 weeks a year, for 19 years. The moving assembly line made this possible and transformed the way that cars are built to this day.

John Berg is a contributing writer for the Alameda Post.